Why Is AC Trunking Essential for Efficient Electrical Distribution Systems

In the realm of electrical distribution systems, the efficiency of power transmission directly influences operational performance and energy management. AC trunking, a critical component of modern electrical infrastructure, facilitates an organized and effective method for distributing alternating current (AC) across extensive facilities and industrial complexes. By employing AC trunking systems, businesses can significantly enhance their electrical efficiency, minimize energy losses, and ensure that power is delivered seamlessly to various equipment and machinery.

Moreover, AC trunking systems are designed to meet the demands of diverse environments, allowing for scalable and flexible electrical installations. Their ability to accommodate multiple circuits within a compact design not only optimizes space but also simplifies maintenance and upgrades. As industries continue to evolve and embrace advanced technologies, the role of AC trunking becomes increasingly vital, offering solutions that align with both current and future electrical distribution needs. This introduction sets the stage for understanding the essential nature of AC trunking in modern electrical distribution systems and its contribution to efficiency and reliability.

The Role of AC Trunking in Electrical Distribution Systems

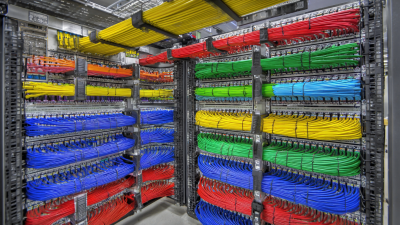

AC trunking plays a crucial role in modern electrical distribution systems, serving as an efficient means of transporting electrical power across various settings. It consists of insulated cable conduits that facilitate the safe and seamless distribution of alternating current. The design of AC trunking allows for easy installation and maintenance, making it an essential component in both residential and commercial infrastructure. By providing a centralized pathway for electrical conductors, AC trunking minimizes the risk of electrical hazards while optimizing space utilization.

Furthermore, AC trunking enhances system reliability and performance. Its robust construction significantly reduces the likelihood of wear and tear associated with traditional wiring methods, thereby prolonging the lifespan of electrical systems. The modular nature of AC trunking systems allows for flexibility in design and scalability, enabling easy upgrades or modifications as electrical demands change over time. This adaptability is especially important in environments where technology evolves rapidly, ensuring that distribution systems remain efficient and capable of handling increased loads without compromising safety.

Electrical Distribution Efficiency: AC Trunking Design

This bar chart represents the efficiency levels of different electrical distribution systems when using AC trunking. The data reflects the improvements in efficiency, measured in percentage, based on the integration of AC trunking in various system designs.

Understanding AC Trunking: Definition and Components

AC trunking is a crucial component in modern electrical distribution systems, designed to streamline the flow of alternating current throughout a facility. Essentially, AC trunking refers to a system of insulated conduits that carry electrical power. These trunking systems consist of several key components, including busbars, connectors, and enclosures, all working together to provide a safer and more efficient means of distributing electricity.

One of the primary functions of AC trunking is to reduce the risk of electrical hazards. By enclosing busbars and wiring within protective housings, AC trunking minimizes exposure to potential electrical faults that could lead to short circuits or fire hazards. This level of protection is essential not only for safety but also for maintaining the integrity of the electrical system.

Tips for installation and maintenance include ensuring that the trunking is adequately rated for the electrical load it will carry. Regular inspections can identify wear or damage, helping to preempt failures. Additionally, keep the trunking clean and free from dust or debris, as these can affect performance and safety. Implementing these practices will aid in sustaining an efficient and reliable electrical distribution system.

Advantages of Using AC Trunking for Power Distribution

AC trunking systems are increasingly recognized for their significant advantages in power distribution, particularly in industrial and commercial settings. One of the primary benefits is their ability to handle high loads efficiently, providing a reliable pathway for electrical distribution without the excessive voltage drop that can occur with traditional wiring methods. This increased efficiency not only supports higher energy demands but also contributes to overall system longevity, reducing the need for frequent maintenance or replacements.

Another advantage of AC trunking lies in its modular design, which allows for flexible configuration and expansion as power requirements evolve. This adaptability is crucial in modern facilities where operational demands can change rapidly. AC trunking systems can accommodate additional circuits with ease, minimizing downtime and providing a scalable solution that can grow alongside the business. Additionally, the enhanced safety and organization that trunking offers—by protecting cables from environmental factors and minimizing the risk of electrical hazards—further solidifies its role as an essential component in efficient electrical distribution systems.

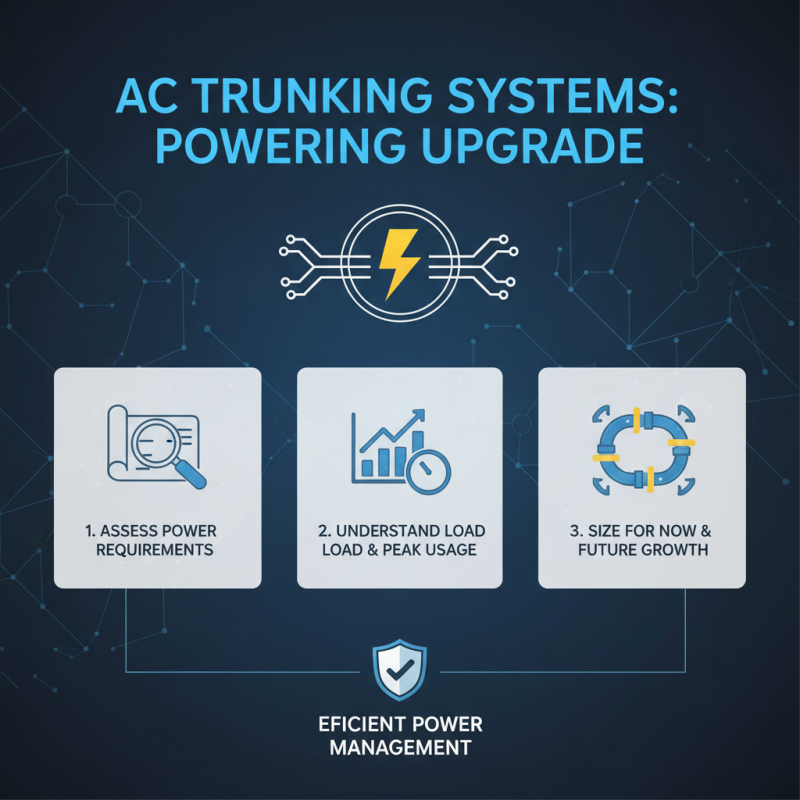

Best Practices for Implementing AC Trunking Systems

Implementing AC trunking systems in electrical distribution is critical for achieving a streamlined and efficient power management process. One of the best practices is to conduct a thorough assessment of the power requirements before design and installation. This involves understanding the load demands, peak usage times, and potential future expansion needs. By accurately gauging these parameters, the trunking system can be sized appropriately, ensuring that it meets current demands while being flexible enough to accommodate future growth without the need for extensive retrofitting.

Another key practice is to ensure proper installation and integration of the AC trunking with existing infrastructure. This necessitates collaboration between designers, engineers, and installation teams to ensure that all components are compatible and that installation guidelines are strictly adhered to. Proper grounding and bonding practices should also be followed to minimize electrical hazards and enhance system stability. Regular maintenance and inspection schedules should be established to ensure that the trunking remains in optimal condition, thus prolonging its lifespan and maintaining system efficiency.

Common Challenges and Solutions in AC Trunking Installations

AC trunking systems play a vital role in the effective distribution of electrical power, yet they often face several installation challenges that can impact their performance. One common issue is the complexity of the installation process, which can arise from inadequate planning and coordination among different contractors. This can lead to alignment problems, increased installation time, and potential safety hazards. To mitigate these risks, it is essential to conduct thorough site assessments and create a detailed layout plan prior to installation. Ensuring that all stakeholders are on the same page can greatly enhance the efficiency of the installation process.

Another challenge associated with AC trunking is the need for proper thermal management. As electrical currents flow through trunking systems, they generate heat, which can affect the integrity of the system if not managed effectively. Insufficient heat dissipation can lead to overheating and potential system failures.

Implementing strategies such as selecting trunking with adequate cooling features and spacing configurations can help in managing thermal issues. Additionally, regular maintenance checks should be scheduled to ensure that the trunking is functioning optimally and to address any wear and tear that may compromise its effectiveness. By addressing these challenges with proactive solutions, AC trunking installations can operate efficiently, contributing to a robust electrical distribution system.

Related Posts

-

Understanding AC Trunking: A Comprehensive Guide to Efficient Cable Management Solutions

-

How to Choose the Right Residential Air Conditioning Installation for Your Home Comfort Needs

-

2025 How to Choose the Best Home Air Conditioning System for Your Needs

-

Top 10 Air Conditioning Systems to Beat the Heat in 2023

-

Understanding the Benefits of an Air Conditioning Box for Energy Efficiency

-

Essential Guide to Home Air Conditioning Installation: Tips for Choosing the Right System for Your Space