How to Select the Best Angle Steel Tower for Your Construction Project

In the realm of construction, choosing the right materials is crucial for ensuring project efficiency and structural integrity. Among the various options available, Angle Steel Towers have gained significant attention due to their versatility and strength. According to a report by the Global Steel Tower Market, the demand for steel towers is projected to grow at a CAGR of 5.2% from 2021 to 2026, underscoring the increasing reliance on these structures in various applications, including telecommunications and power transmission. However, selecting the best Angle Steel Tower can pose challenges, particularly concerning design specifications, load-bearing requirements, and environmental resistance. This blog will delve into the potential problems associated with different types of angle steel towers, offering insights and solutions for construction professionals aiming to make informed decisions for their projects.

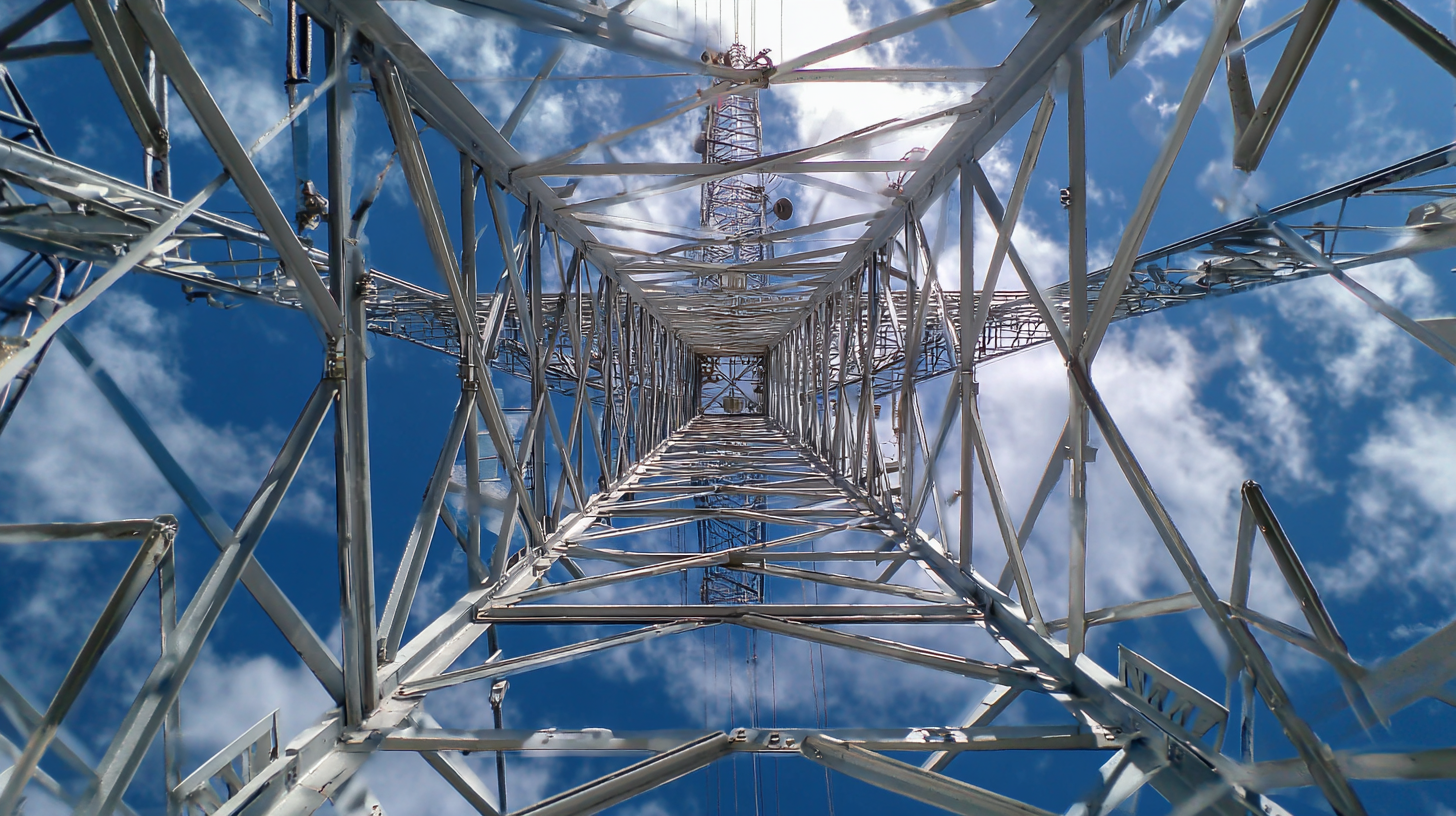

Understanding the Importance of Angle Steel Towers in Construction

Angle steel towers play a crucial role in various construction projects, acting as essential structural components for supporting power lines, telecommunication systems, and even wind turbines. According to a recent report from the Global Steel Tower Market, the demand for angle steel towers is projected to grow at a compound annual growth rate (CAGR) of 5.7% through 2026, driven by the increasing need for improved infrastructure and energy efficiency. These towers are preferred for their outstanding strength-to-weight ratio, which enhances stability while minimizing material costs.

Moreover, the design and selection of angle steel towers are significantly influenced by factors such as load requirements, environmental conditions, and the specific application type. The American Institute of Steel Construction highlights that angle steel's versatility allows for customized solutions tailored to project needs, making it indispensable in modern construction.

For example, as reported by the International Energy Agency, the move towards sustainable energy solutions has led to a surge in demand for renewable energy infrastructure, further solidifying the importance of durable angle steel towers in facilitating these developments.

Key Factors to Consider When Choosing Angle Steel Towers

When selecting the best angle steel tower for your construction project, there are several key factors to consider to ensure durability and performance. First, it is crucial to evaluate the load capacity required for your specific application. According to the International Tower and Steel Structure Association, towers should be designed to withstand a minimum of 1.5 times the expected load to account for dynamic stresses and environmental factors. Ensuring that the angles and thickness of the steel are adequate for these demands is essential in preventing structural failures.

Another important aspect is the environmental conditions where the tower will be installed. The American Institute of Steel Construction (AISC) highlights that towers in coastal areas should use corrosion-resistant materials to withstand the effects of saltwater and high winds. Additionally, understanding local regulations and standards is vital, as they often dictate specific requirements for design and materials based on geographic and climatic conditions. Conducting a thorough site assessment can help determine these factors and guide the selection process effectively.

Steel Tower Height vs. Load Capacity

This chart illustrates the relationship between the height of angle steel towers and their corresponding load capacity. As the height of the tower increases, the load capacity also rises, making it crucial to choose the appropriate tower height for your construction needs.

Comparing Different Types of Angle Steel Towers: Pros and Cons

When selecting the best angle steel tower for your construction project, it is essential to understand the various types available, each with its unique advantages and disadvantages. Common types include lattice towers, monopole towers, and tubular towers. Lattice towers are known for their lightweight and cost-effectiveness, making them an attractive choice for projects with budget constraints. According to a report from the American Institute of Steel Construction, lattice towers can achieve over 25% savings in material costs compared to traditional designs, but they may require more site space and have a lower aesthetic appeal.

On the other hand, monopole towers are favored for their sleek design and smaller footprint, often suited for urban environments where space is limited. A study conducted by the International Journal of Structural Engineering highlighted that monopole towers can withstand high wind loads better than lattice structures, making them ideal for regions prone to harsh weather. However, they typically come at a higher installation cost, which can be a significant factor for budget-conscious projects.

Tubular towers provide a robust option, achieving excellent stability and strength, particularly for large-scale applications. Research indicates that tubular designs can endure significant environmental stress, with a lifespan that often exceeds 30 years. While their initial costs may be higher, the longevity and reduced maintenance requirements can offer overall value in large construction projects. Ultimately, the choice of angle steel tower will depend on specific project needs, budget considerations, and environmental factors, necessitating a thorough evaluation of each type's pros and cons.

Future Trends in Angle Steel Tower Design and Materials

The future of angle steel tower design is rapidly evolving, driven by advancements in materials and engineering techniques. One prominent trend is the increasing use of high-strength steel alloys, which provide superior durability and reduce the overall weight of the structures. This shift not only enhances performance under varying environmental conditions but also allows for more streamlined design options that can better accommodate aesthetic considerations without compromising structural integrity. Furthermore, the incorporation of smart technology into angle steel towers is gaining traction, enabling real-time monitoring and maintenance capabilities that enhance safety and efficiency.

Sustainability is another critical aspect influencing future designs. Manufacturers are focusing on eco-friendly materials and construction methods, including the use of recycled steel and reducing waste during the building process. This trend aligns with global efforts to minimize carbon footprints and promote greener construction practices. Additionally, modular construction techniques are becoming more prevalent, allowing for quicker assembly and disassembly of angle steel towers, thus offering flexibility in project planning. As these trends continue to develop, they promise to reshape the landscape of angle steel tower design, making them more resilient, efficient, and environmentally responsible.

Best Practices for Installation and Maintenance of Angle Steel Towers

When it comes to the installation and maintenance of angle steel towers, adhering to best practices is crucial for ensuring structural integrity and longevity. According to a report from the Steel Construction Institute, nearly 30% of structural failures can be traced back to improper installation techniques. Therefore, it is essential to ensure that all components are fabricated and assembled in strict accordance with manufacturer specifications. Regular inspections during the construction phase can mitigate potential issues and enhance the overall stability of the structure.

When it comes to the installation and maintenance of angle steel towers, adhering to best practices is crucial for ensuring structural integrity and longevity. According to a report from the Steel Construction Institute, nearly 30% of structural failures can be traced back to improper installation techniques. Therefore, it is essential to ensure that all components are fabricated and assembled in strict accordance with manufacturer specifications. Regular inspections during the construction phase can mitigate potential issues and enhance the overall stability of the structure.

Moreover, routine maintenance is key to prolonging the lifespan of angle steel towers. The American Institute of Steel Construction emphasizes that periodic assessments, at least once every three years, can significantly reduce corrosion risk and detect wear before it compromises safety. Additionally, applying protective coatings and performing timely repairs can increase the resilience of the towers against environmental factors, enhancing their operational efficiency. By following these guidelines, construction operators can optimize their projects’ reliability and reduce long-term costs associated with repairs and replacements.