How to Choose the Best Wire Mesh Weaving Machine for Your Needs?

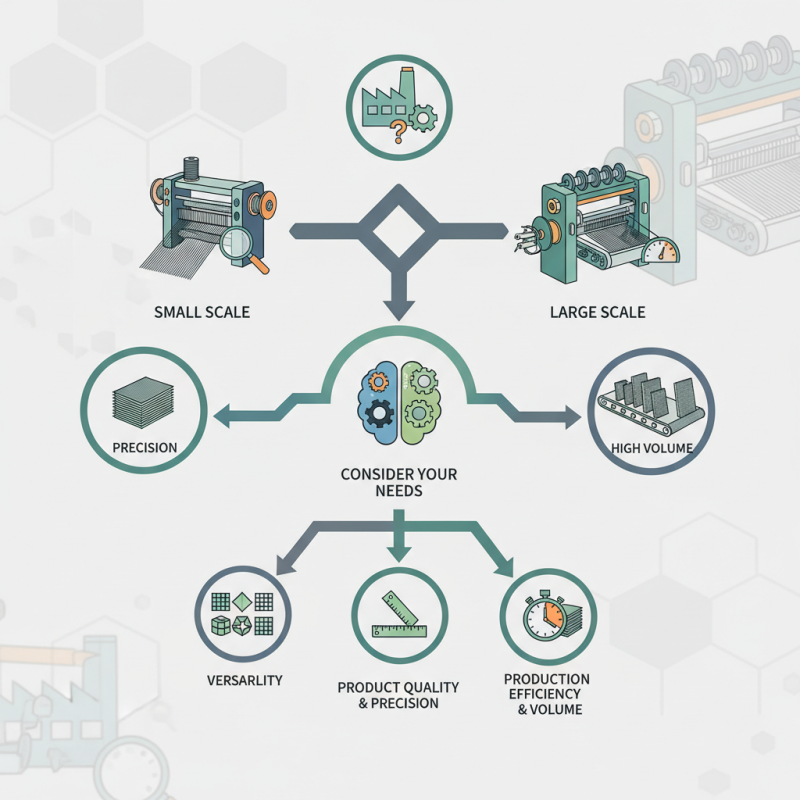

Choosing the right wire mesh weaving machine is crucial for various industries. It affects production efficiency and product quality significantly. The market offers numerous options, which can be overwhelming.

Consider your specific needs. Different machines weave different types of wire mesh. Some machines work faster, while others focus on precision. Always think about the volume of production. A machine that suits small-scale operations may not be ideal for larger ones.

Many buyers overlook the importance of machine features. You may need a machine with versatility. Some machines can weave multiple types of mesh, offering more flexibility. Reflect on your own requirements; this can lead to better decisions. Overall, selecting the best wire mesh weaving machine involves careful thought and consideration of your unique needs.

Understanding Your Wire Mesh Weaving Needs

Understanding your wire mesh weaving needs is crucial for selecting the right machine. Start by assessing the types of mesh you plan to produce. Consider wire diameter, mesh size, and the materials involved. Different applications require distinct specifications. For example, heavy-duty meshes are often used in industrial settings, while finer meshes suit architectural or decorative purposes.

Next, think about the production volume you expect. Higher demand may necessitate a more advanced machine. It could also lead to higher initial costs. Balancing efficiency and budget is essential. Sometimes, the cheaper option may have hidden drawbacks, such as lower output quality or durability issues. Reflect on the long-term implications of your choice.

Don’t forget about maintenance and support. Some machines might require frequent adjustments or repairs. Evaluate your team's technical skills. If you lack expertise, consider investing in training. A perfect solution shouldn't be the only focus. It's vital to find a machine that aligns well with your operational capabilities. This balance can lead to a smoother production process, ultimately affecting your overall business success.

Types of Wire Mesh Weaving Machines Available

When selecting a wire mesh weaving machine, understanding the types available is crucial. There are mainly three categories: manual, semi-automatic, and fully automatic machines. Each type serves different production needs. Manual machines offer low initial costs but require significant labor. On the other hand, semi-automatic options enhance productivity while being more affordable than fully automatic units.

Fully automatic machines are sophisticated. They handle large volumes of wire mesh with minimal human intervention. Recent reports indicate that the demand for fully automatic machines is rising, driven by efficiency and reduced labor costs. In fact, market research suggests these machines could account for up to 70% of sales in the coming years.

**Tip:** Assess your production capacity before investing. A smaller shop may not need a fully automatic unit. Evaluate your budget carefully; cutting corners can lead to future headaches. Investing in a reliable machine can enhance your product quality and consistency. Ensure it meets your specific weaving requirements. Your choice will shape your operation's efficiency and profitability.

Types of Wire Mesh Weaving Machines and Their Production Capacities

Key Features to Consider in a Weaving Machine

When selecting a wire mesh weaving machine, several key features should be on your checklist. One important aspect is the machine's capacity. Consider the thickness and type of wire you plan to use. Machines vary in their ability to handle heavy-duty materials versus lighter ones. A machine that is too weak may struggle, leading to inefficiencies. It’s better to invest in a model that meets your production goals without being excessive in power.

Another crucial feature is the machine's adaptability. Look for models that can easily switch between different mesh types. A flexible machine saves time and reduces the need for multiple devices. Ease of operation is also vital. User-friendly controls and straightforward maintenance can make a significant difference in daily operations. Machines that require constant troubleshooting can quickly become frustrating.

Finally, pay attention to the warranty and support services. Understand that issues may arise. A machine with limited support can lead to downtime. Not all manufacturers provide adequate assistance. Sometimes, a strong warranty might look good but lacks real support. Reflect on your specific needs and future requirements before making a decision. Balancing power, adaptability, and support in your choice will yield better long-term results.

Assessing Budget and Cost-Effectiveness

Assessing your budget is crucial when choosing a wire mesh weaving machine. Reports indicate that equipment can range from a few thousand to over a hundred thousand dollars, depending on features and capabilities. The initial price tag often overshadows long-term costs. Regular maintenance and spare parts can add to ongoing expenses.

Cost-effectiveness is about more than just upfront costs. A machine that seems affordable may lack efficiency, leading to higher operational costs. Industry studies show that machines with better automation and higher throughput can lower labor costs significantly. For instance, automated systems can reduce labor requirements by as much as 35%. This reduction can make a more expensive machine a better choice over time.

Consider the unique needs of your production line. A machine that fits well in terms of budget may not meet production demands. Conversely, an expensive machine may be too complex for simple tasks. Therefore, assess both current and future needs carefully. Preparing a detailed cost analysis can uncover hidden expenses. It's not only about what you invest initially, but how it impacts overall efficiency and productivity in the long run.

Maintenance and Support for Your Chosen Machine

When selecting a wire mesh weaving machine, maintenance and support are crucial factors. Regular maintenance ensures the longevity of your machine. Regularly checking parts can prevent major breakdowns. Tightening bolts and cleaning components is essential. Even small neglect can lead to costly repairs.

Tips: Schedule routine inspections. Create a maintenance log. This helps identify patterns and recurring issues. Also, ensure spare parts are readily available. Waiting for parts can delay production. This might hinder your business operations.

Training your staff on machine operation is also vital. A knowledgeable operator can troubleshoot minor issues. This reduces downtime and reliance on external support. However, overconfidence can lead to mistakes. Striking a balance is necessary. Regular training updates are beneficial to keep skills sharp. While mistakes are part of learning, aim to minimize them through continuous education.