Top 10 Air Conditioning Duct Types for Efficient Cooling Solutions?

Air conditioning ducts play a crucial role in cooling efficiency. According to the U.S. Department of Energy, homes lose 30% of heating and cooling energy due to inefficient duct systems. Selecting the right air conditioning duct type can significantly improve energy efficiency and air quality.

Different duct styles cater to various needs. For example, flexible ducts offer easy installation, while rigid ducts tend to provide better airflow. However, flexibility can lead to bending and reduced efficiency if not installed correctly.

While considering duct options, it's essential to weigh their advantages and drawbacks. Some materials may have better insulation properties, while others might be more affordable. Proper insulation helps to enhance energy savings. Understanding these factors can refine your choice for optimal cooling solutions.

Types of Air Conditioning Ducts: Overview and Importance in HVAC Systems

Air conditioning ducts play a crucial role in HVAC systems. They are vital for distributing cooled air throughout a building. Various types of ducts exist, including flexible, rigid, and ductboard options. Each type has unique strengths and weaknesses. For instance, flexible ducts are easier to install but may have airflow restrictions. Rigid ducts, however, often provide better efficiency and performance.

According to a report from the U.S. Department of Energy, properly sealed and insulated ducts can improve energy efficiency by up to 20%. This shows the significant impact ducts have on HVAC performance. When selecting duct types, consider the layout and design of your space. The choices can lead to drastic differences in energy consumption.

Furthermore, the wrong duct type can lead to issues like air leaks and noise. It can often mean higher energy bills. Investing time in choosing the right ducts is essential for a comfortable and energy-efficient environment. Balancing cost and performance will ensure better climate control.

Top 10 Air Conditioning Duct Types for Efficient Cooling Solutions

This bar chart illustrates the popularity and efficiency ratings of various air conditioning duct types, from flexible ducts to return air ducts. A higher rating indicates better efficiency and usage in HVAC systems.

Material Comparisons: Rigid vs. Flexible Ducts in Cooling Efficiency

When it comes to cooling efficiency, the choice of duct material plays a significant role. Rigid ducts are typically made from metal or fiberglass. They can withstand high air pressure, ensuring minimal air leakage. This can lead to more consistent cooling throughout a space. However, they can be expensive to install and may require more space. This can be a challenge in smaller buildings.

On the other hand, flexible ducts are made from softer materials. They are easier to install in tight spaces. They can bend around obstacles, which is often a great advantage. But, their flexibility can sometimes lead to inefficiencies. If not properly secured, these ducts may crimp or sag, which restricts airflow. It's a fine balance between ease of installation and effectiveness.

Ultimately, the choice between rigid and flexible ducts should consider the specific needs of the building and its layout. Cost, space, and air quality all factor into the decision. Reflecting on your options and potential drawbacks can guide you to make a better choice for cooling efficiency.

Top 10 Air Conditioning Duct Types for Efficient Cooling Solutions

| Duct Type | Material | Cooling Efficiency | Installation Difficulty | Cost | Durability |

|---|---|---|---|---|---|

| Rigid Metal Ducts | Galvanized Steel | High | Moderate | $$$ | Very High |

| Flexible Ducts | Plastic | Medium | Easy | $ | Moderate |

| Insulated Ducts | Foam or Fiber | High | Moderate | $$ | High |

| Sheet Metal Ducts | Aluminum | High | Difficult | $$$ | Very High |

| Fiberboard Ducts | Fiberboard | Medium | Easy | $$ | Moderate |

| Spiral Ducts | Metal | High | Moderate | $$$ | Very High |

| PVC Ducts | PVC | Medium | Easy | $ | Low |

| R-8 Insulated Ducts | Fiberglass | High | Moderate | $$$ | High |

| Airflow Control Ducts | Various | Medium | Difficult | $$$ | High |

| Round Ducts | Metal or Flexible Material |

High | Easy | $$ | High |

Insulation Methods: Enhancing Energy Efficiency for Ducted AC Systems

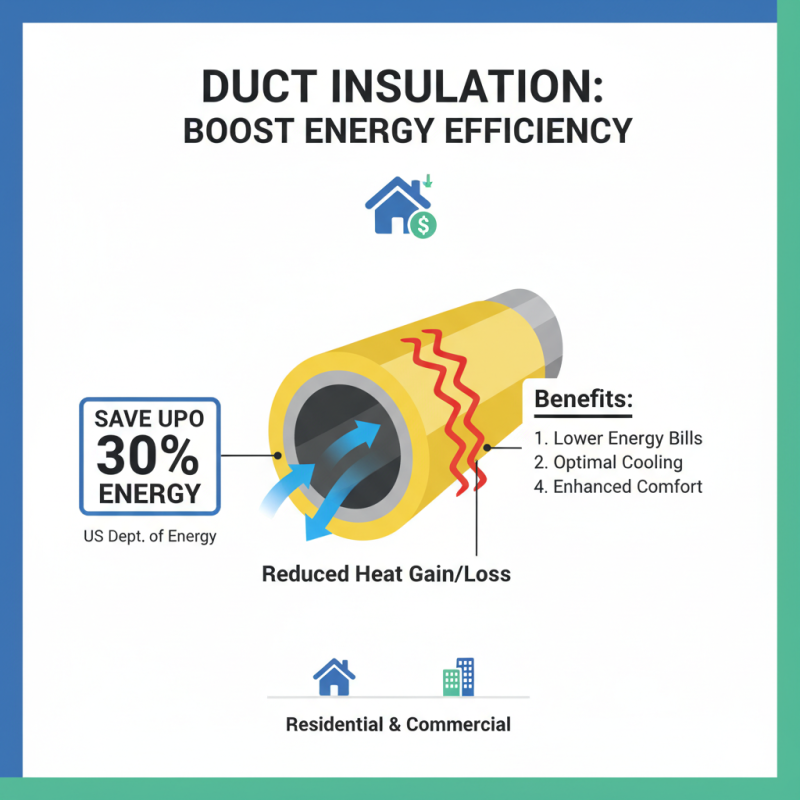

When it comes to ducted air conditioning systems, insulation plays a crucial role in enhancing energy efficiency. Proper insulation minimizes heat loss and gain, which ultimately supports optimal cooling. According to the U.S. Department of Energy, insulated ducts can reduce energy losses by up to 30%. This is significant for both residential and commercial buildings aiming for lower energy bills.

Different insulation methods exist, such as fiberglass, foam board, and reflective insulation. Each has its own set of benefits and drawbacks. For instance, fiberglass insulation is affordable and effective, but it may not provide the highest R-value compared to foam board. Proper installation is essential; gaps and compressions can reduce effectiveness quickly. Therefore, investing in skilled professionals for duct insulation is crucial. It’s estimated that poorly insulated duct systems can waste up to 40% of the energy used for heating and cooling.

Additionally, regularly inspecting and maintaining duct systems can identify inefficiencies. Even well-insulated ducts can develop leaks over time. Sealing these leaks can improve airflow and system performance. As per the Environmental Protection Agency, sealing ducts can improve HVAC efficiency by up to 20%. Such measures are vital for a sustainable and economical approach to air conditioning. Ignoring these issues could lead to higher costs and unnecessary energy waste.

Sizing Considerations: How Duct Size Affects Airflow and Comfort

When considering air conditioning ducts, sizing is crucial. Properly sized ducts enhance airflow and improve comfort levels. According to the ASHRAE Handbook, airflow can drop by 50% if ducts are too small. This results in uneven cooling in rooms. A common mistake is underestimating duct size during installation.

A well-sized duct ensures adequate air distribution. For example, a 6-inch duct may deliver around 160 CFM (cubic feet per minute) at 0.1 inches of static pressure. On the other hand, a 4-inch duct would only push about 70 CFM. Insufficient duct size can lead to hot spots and increased energy bills. Homeowners often overlook this when planning their HVAC systems.

It's important to assess the layout of your space. Long, winding ducts can also impact efficiency. A direct path provides better airflow. Many homeowners fail to realize that airflow resistance increases in poorly designed systems. This can lead to discomfort and higher operating costs. Regular inspections can help identify sizing issues. Balancing duct sizes requires careful evaluation to achieve optimal cooling.

Innovations in Duct Design: Impact on Air Quality and Energy Savings

Innovations in duct design have a significant impact on air quality and energy efficiency. New materials and techniques help create ducts that minimize leaks. This design shift improves airflow and reduces energy waste. Smooth surfaces inside ducts prevent dust buildup. Cleaner air circulates through living spaces, contributing to better health. Traditional ducts often trap allergens, compromising indoor air quality.

Flexible duct systems are gaining popularity. Their adaptability allows for efficient cooling in various types of buildings. However, not all installations are executed perfectly. Poor placement can lead to air leaks, which counteract intended benefits. Regular maintenance is crucial to check for blockages or damage. Observations show that homeowners who neglect this aspect often deal with higher energy bills.

Another interesting development is the use of smart technology. Sensors can monitor airflow and temperature. They adjust systems in real time to maximize efficiency. Yet, reliance on technology can sometimes lead to overconfidence. Users may overlook manual inspections, believing everything is functioning correctly. Balancing technology and proactive maintenance is necessary for optimal performance.

Related Posts

-

How to Clean Air Conditioning Ducts for Optimal Performance

-

Understanding the Importance of Proper Air Conditioning Duct Installation for Energy Efficiency

-

Top 5 Air Conditioning and Installation Tips for a Cool Home This Summer

-

What is a Home Air Conditioning System and How Does It Work

-

Top 10 Best Residential Air Conditioning Systems for Ultimate Comfort?

-

2026 Top Domestic Air Conditioning Trends You Should Know?