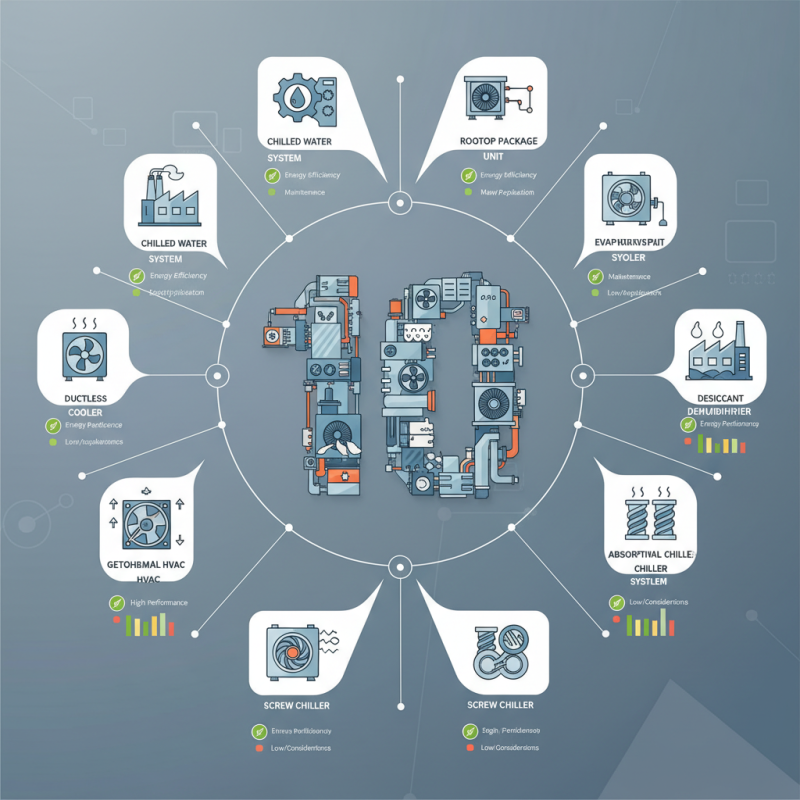

Top 10 Industrial Air Conditioning Systems for Optimal Performance?

When it comes to industrial air conditioning, performance is crucial. The right system can enhance productivity and ensure comfort. In various industries, temperature regulation is vital. A well-functioning air conditioning system can impact employee efficiency and equipment longevity.

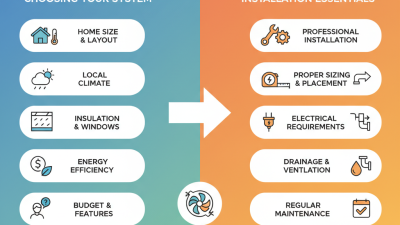

Choosing the optimal industrial air conditioning system involves understanding specific needs. Different environments require different solutions. From manufacturing plants to warehouses, the demands vary greatly. Factors like energy efficiency, capacity, and maintenance costs must be considered.

Not all systems are created equal, and some may fall short of expectations. Hidden costs and inefficiencies can arise without careful evaluation. Reflecting on these aspects is essential for making informed decisions. In this guide, we will explore the top 10 systems available today. Each selection highlights key features and potential drawbacks. This way, businesses can find the best fit for their needs.

Top 10 Industrial Air Conditioning Systems: Overview and Importance

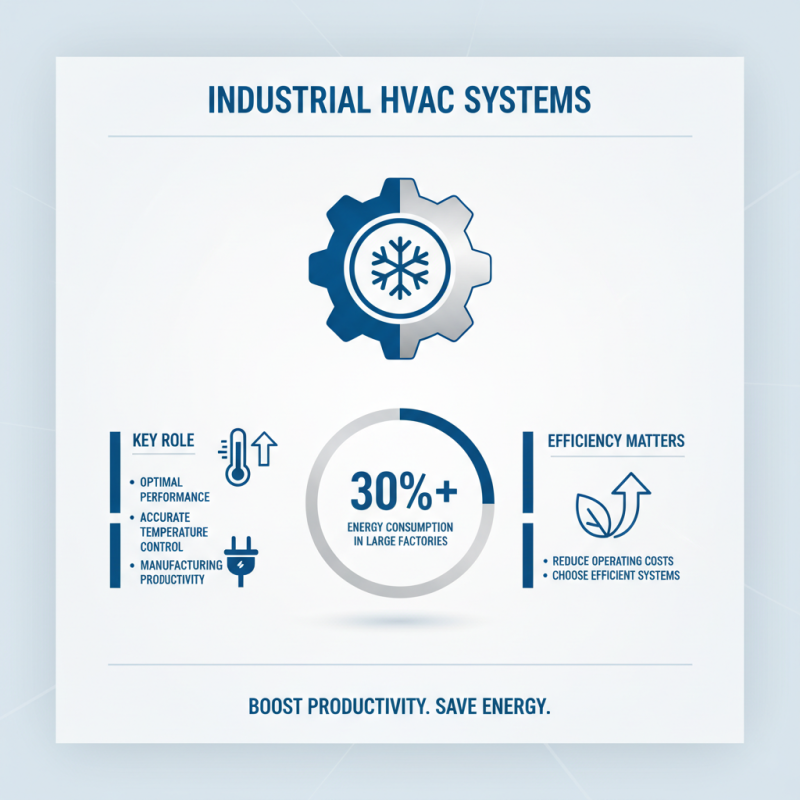

Industrial air conditioning systems play a crucial role in maintaining optimal performance across various sectors. Accurate temperature control ensures productivity in manufacturing spaces. Reports indicate that over 30% of energy consumption in large factories is attributed to HVAC systems. This significant figure depicts the importance of choosing efficient systems.

Modern industrial air conditioning units offer advanced features like variable refrigerant flow and smart controls. These technologies allow for precise climate control and energy savings. However, installation can be complex. Many facilities struggle with selecting the right system. Poor choices often lead to increased operational costs.

Regular maintenance is essential to sustain efficiency. Studies show that neglected systems can lose up to 40% of their efficiency. This loss can severely impact production and comfort levels. Investing in high-quality systems and preventive maintenance can lead to better results. The challenge lies in balancing initial costs with long-term savings.

Evaluating Performance Metrics of Industrial Air Conditioning Systems

When selecting industrial air conditioning systems, performance metrics play a crucial role. Key metrics include energy efficiency, cooling capacity, and airflow distribution. Energy efficiency ratings indicate how much cooling is provided per unit of energy consumed. A higher rating often correlates with lower operational costs.

Cooling capacity defines how well a system can handle the thermal load. It’s vital to match the unit’s capacity to the facility's needs. Oversized systems may lead to excessive cycling, lowering their lifespan. Meanwhile, undersized systems struggle to maintain the desired temperature, leading to discomfort and potential equipment issues.

Tips: Regular maintenance checks can prevent efficiency drop-offs. Dirty filters or blocked coils can significantly reduce performance. Consider implementing a monitoring system for real-time data. This helps in promptly addressing any inefficiencies.

Remember, sometimes systems operate under less-than-ideal conditions. Monitoring and adjusting to fluctuations can help in achieving optimal performance. Recognizing these challenges will ultimately lead to more informed decisions and improved outcomes.

Key Features and Technologies in Leading Air Conditioning Solutions

In today's industrial landscape, efficient air conditioning systems are vital for maintaining optimal performance. Leading solutions often feature advanced technologies, such as variable refrigerant flow (VRF) systems. These systems adjust the flow of refrigerant based on cooling needs, enhancing energy efficiency. Many facilities see significant reductions in energy consumption, but installation can be complex.

Innovative controls are essential in modern air conditioning systems. Smart thermostats allow for precise temperature adjustments. They provide real-time data and can be integrated with building management systems. However, users may find the learning curve steep. Additionally, air quality is critical in industrial settings. Some systems incorporate advanced filters to remove pollutants, but these can require frequent maintenance.

Another noteworthy feature is the modular design of certain systems. They enable scalability, allowing businesses to adjust capacity as needed. Yet, this flexibility may come with higher initial costs. It’s crucial to evaluate long-term benefits versus upfront investments. Sometimes, the best choice isn’t immediately obvious.

Energy Efficiency Standards and Regulations for Industrial Systems

Energy efficiency is critical in industrial air conditioning systems. Regulations vary by region, but they often push for lower energy consumption. This can reduce operational costs significantly. Energy-efficient systems lower greenhouse gas emissions. They contribute to more sustainable practices in manufacturing and other sectors.

Compliance with energy efficiency standards can be challenging. Many companies struggle to stay updated on changing regulations. Some systems may not meet the latest requirements. Regular audits are essential for evaluating energy use. Many businesses find it difficult to balance compliance and operational needs.

Energy assessment can uncover inefficiencies. Regular maintenance helps in optimizing performance. However, this often gets neglected. Employees may lack training on updated systems. These gaps highlight the need for investment in knowledge and infrastructure to improve energy efficiency.

Top 10 Industrial Air Conditioning Systems for Optimal Performance

This chart illustrates the energy efficiency ratings of the top 10 industrial air conditioning systems based on various performance metrics, including SEER (Seasonal Energy Efficiency Ratio) and EER (Energy Efficiency Ratio).

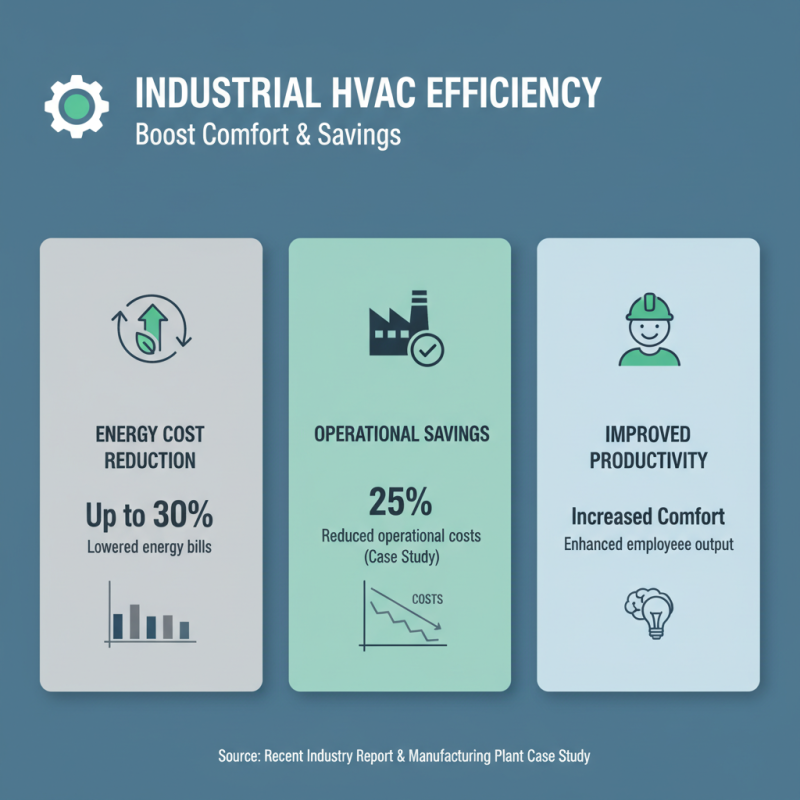

Case Studies: Successful Implementations of Top Air Conditioning Systems

Industrial air conditioning systems play a crucial role in maintaining a comfortable and productive environment. A recent industry report found that efficient systems can reduce energy costs by up to 30%. One case study involved a manufacturing plant that implemented an integrated HVAC solution. This led to a 25% reduction in operational costs and improved employee productivity.

Another real-world example highlights a logistics center that optimized its cooling systems. By utilizing advanced sensors and automation, the center achieved better temperature control and reduced energy consumption. The result? An impressive 20% decrease in energy bills. However, it's important to consider the initial investment and ongoing maintenance of these systems. Not every installation yields immediate savings.

The effectiveness of air conditioning systems often hinges on proper design and implementation. An aerospace facility faced challenges with inconsistent cooling. After reevaluating their system configuration, they managed to achieve a more stable environment, but it took time and further investment. This shows that while top air conditioning systems promise performance, they require careful planning and periodic adjustments to truly excel.

Related Posts

-

Top 5 Air Conditioning and Installation Tips for a Cool Home This Summer

-

2025 How to Choose the Best Residential Air Conditioning Systems for Your Home

-

Why You Should Consider Residential Air Conditioning for Your Home Comfort

-

How to Choose the Right Air Conditioning Systems and Services for Your Home

-

How to Improve Air Conditioning Efficiency at Home?

-

10 Essential Tips for Choosing and Installing Air Conditioning Systems